Poly (methyl Methacrylate) on:

[Wikipedia]

[Google]

[Amazon]

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called

PMMA is a strong, tough, and lightweight material. It has a density of 1.17–1.20 g/cm3, which is less than half that of glass.Polymethylmethacrylate (PMMA, Acrylic)

PMMA is a strong, tough, and lightweight material. It has a density of 1.17–1.20 g/cm3, which is less than half that of glass.Polymethylmethacrylate (PMMA, Acrylic)

. Makeitfrom.com. Retrieved 2015-03-23. It also has good impact strength, higher than both glass and polystyrene; however, PMMA's impact strength is still significantly lower than polycarbonate and some engineered polymers. PMMA ignites at and combustion, burns, forming carbon dioxide, water, carbon monoxide, and low-molecular-weight compounds, including formaldehyde. PMMA transmittance, transmits up to 92% of visible light (3 mm thickness), and gives a reflection of about 4% from each of its surfaces due to its refractive index (1.4905 at 589.3 nm).Refractive index and related constants – Poly(methyl methacrylate) (PMMA, Acrylic glass)

. Refractiveindex.info. Retrieved 2014-10-27. It filters ultraviolet (UV) light at wavelengths below about 300 nanometre, nm (similar to ordinary window glass). Some manufacturers add coatings or additives to PMMA to improve absorption in the 300–400 nm range. PMMA passes infrared light of up to 2,800 nm and blocks IR of longer wavelengths up to 25,000 nm. Colored PMMA varieties allow specific IR wavelengths to pass while blocking visible spectrum, visible light (for remote control or heat sensor applications, for example). PMMA swells and dissolves in many organic solvents; it also has poor resistance to many other chemicals due to its easily hydrolysis, hydrolyzed ester groups. Nevertheless, its environmental stability is superior to most other plastics such as polystyrene and polyethylene, and therefore it is often the material of choice for outdoor applications. PMMA has a maximum water absorption ratio of 0.3–0.4% by weight.DATA TABLE FOR: Polymers: Commodity Polymers: PMMA

. Matbase.com. Retrieved 2012-05-09. Tensile strength decreases with increased water absorption. Its coefficient of thermal expansion is relatively high at (5–10)×10−5 °C−1.

* PMMA is commonly used for constructing residential and commercial aquariums. Designers started building large aquariums when poly(methyl methacrylate) could be used. It is less often used in other building types due to incidents such as the Summerland disaster.

* PMMA is used for viewing ports and even complete pressure hulls of submersibles, such as the Alicia (submarine), ''Alicia'' submarine's viewing sphere and the window of the bathyscaphe Trieste.

* PMMA is used in the lenses of exterior lights of automobiles.

* Spectator protection in ice hockey rinks is made from PMMA.

* Historically, PMMA was an important improvement in the design of aircraft windows, making possible such designs as the bombardier's transparent nose compartment in the Boeing B-17 Flying Fortress. Modern aircraft transparencies often use stretched acrylic plies.

* Police vehicles for riot control often have the regular glass replaced with PMMA to protect the occupants from thrown objects.

* PMMA is an important material in the making of certain lighthouse lenses.

* PMMA was used for the roofing of the compound in the Olympiapark, Munich, Olympic Park for the 1972 Summer Olympics in Munich. It enabled a light and translucent construction of the structure.

* PMMA (under the brand name "Lucite") was used for the ceiling of the Reliant Astrodome, Houston Astrodome.

* PMMA is commonly used for constructing residential and commercial aquariums. Designers started building large aquariums when poly(methyl methacrylate) could be used. It is less often used in other building types due to incidents such as the Summerland disaster.

* PMMA is used for viewing ports and even complete pressure hulls of submersibles, such as the Alicia (submarine), ''Alicia'' submarine's viewing sphere and the window of the bathyscaphe Trieste.

* PMMA is used in the lenses of exterior lights of automobiles.

* Spectator protection in ice hockey rinks is made from PMMA.

* Historically, PMMA was an important improvement in the design of aircraft windows, making possible such designs as the bombardier's transparent nose compartment in the Boeing B-17 Flying Fortress. Modern aircraft transparencies often use stretched acrylic plies.

* Police vehicles for riot control often have the regular glass replaced with PMMA to protect the occupants from thrown objects.

* PMMA is an important material in the making of certain lighthouse lenses.

* PMMA was used for the roofing of the compound in the Olympiapark, Munich, Olympic Park for the 1972 Summer Olympics in Munich. It enabled a light and translucent construction of the structure.

* PMMA (under the brand name "Lucite") was used for the ceiling of the Reliant Astrodome, Houston Astrodome.

* Acrylic paint essentially consists of PMMA suspended in water; however since PMMA is hydrophobe, hydrophobic, a substance with both hydrophobic and hydrophilic groups needs to be added to facilitate the suspension (chemistry), suspension.

* Modern furniture makers, especially in the 1960s and 1970s, seeking to give their products a space age aesthetic, incorporated Lucite and other PMMA products into their designs, especially office chairs. Many other products (for example, guitars) are sometimes made with acrylic glass to make the commonly opaque objects translucent.

* Perspex has been used as a surface to paint on, for example by Salvador Dalí.

* Diasec is a process which uses acrylic glass as a substitute for normal glass in picture frames. This is done for its relatively low cost, light weight, shatter-resistance, aesthetics and because it can be ordered in larger sizes than standard picture framing glass.

* As early as 1939, Los Angeles-based Dutch sculptor Jan de Swart, Jan De Swart experimented with samples of Lucite sent to him by DuPont; De Swart created tools to work the Lucite for sculpture and mixed chemicals to bring about certain effects of color and refraction.

* From approximately the 1960s onward, sculptors and glass artists such as Jan Kubíček, Leroy Lamis, and Frederick Hart (sculptor), Frederick Hart began using acrylics, especially taking advantage of the material's flexibility, light weight, cost and its capacity to refract and filter light.

* In the 1950s and 1960s, Lucite was an extremely popular material for jewelry, with several companies specialized in creating high-quality pieces from this material. Lucite beads and ornaments are still sold by jewelry suppliers.

* Acrylic Sheets are produced in dozens of standard colors, most commonly sold using color numbers developed by Rohm & Haas in the 1950s.

* Acrylic paint essentially consists of PMMA suspended in water; however since PMMA is hydrophobe, hydrophobic, a substance with both hydrophobic and hydrophilic groups needs to be added to facilitate the suspension (chemistry), suspension.

* Modern furniture makers, especially in the 1960s and 1970s, seeking to give their products a space age aesthetic, incorporated Lucite and other PMMA products into their designs, especially office chairs. Many other products (for example, guitars) are sometimes made with acrylic glass to make the commonly opaque objects translucent.

* Perspex has been used as a surface to paint on, for example by Salvador Dalí.

* Diasec is a process which uses acrylic glass as a substitute for normal glass in picture frames. This is done for its relatively low cost, light weight, shatter-resistance, aesthetics and because it can be ordered in larger sizes than standard picture framing glass.

* As early as 1939, Los Angeles-based Dutch sculptor Jan de Swart, Jan De Swart experimented with samples of Lucite sent to him by DuPont; De Swart created tools to work the Lucite for sculpture and mixed chemicals to bring about certain effects of color and refraction.

* From approximately the 1960s onward, sculptors and glass artists such as Jan Kubíček, Leroy Lamis, and Frederick Hart (sculptor), Frederick Hart began using acrylics, especially taking advantage of the material's flexibility, light weight, cost and its capacity to refract and filter light.

* In the 1950s and 1960s, Lucite was an extremely popular material for jewelry, with several companies specialized in creating high-quality pieces from this material. Lucite beads and ornaments are still sold by jewelry suppliers.

* Acrylic Sheets are produced in dozens of standard colors, most commonly sold using color numbers developed by Rohm & Haas in the 1950s.

* PMMA, in the commercial form Technovit 7200 is used vastly in the medical field. It is used for plastic histology, electron microscopy, as well as many more uses.

* PMMA has been used to create ultra-white opaque membranes that are flexible and switch appearance to transparent when wet.

* Acrylic is used in tanning beds as the transparent surface that separates the occupant from the tanning bulbs while tanning. The type of acrylic used in tanning beds is most often formulated from a special type of polymethyl methacrylate, a compound that allows the passage of ultraviolet rays.

* Sheets of PMMA are commonly used in the sign industry to make flat cut out letters in thicknesses typically varying from . These letters may be used alone to represent a company's name and/or logo, or they may be a component of illuminated channel letters. Acrylic is also used extensively throughout the sign industry as a component of wall signs where it may be a backplate, painted on the surface or the backside, a faceplate with additional raised lettering or even photographic images printed directly to it, or a spacer to separate sign components.

* PMMA was used in Laserdisc optical media. (Compact Disc, CDs and DVDs use both acrylic and polycarbonate for impact resistance).

* It is used as a light guide for the backlights in TFT LCD, TFT-LCDs.

* Plastic optical fiber used for short-distance communication is made from PMMA, and perfluorinated PMMA, clad with fluorinated PMMA, in situations where its flexibility and cheaper installation costs outweigh its poor heat tolerance and higher attenuation versus glass fiber.

* PMMA, in a purified form, is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.

* In semiconductor research and industry, PMMA aids as a resist (semiconductor fabrication), resist in the electron beam lithography process. A solution consisting of the polymer in a solvent is used to spin coating, spin coat silicon and other semiconducting and semi-insulating wafers with a thin film. Patterns on this can be made by an electron beam (using an electron microscope), deep UV light (shorter wavelength than the standard photolithography process), or X-rays. Exposure to these creates chain scission or (de-cross-linking) within the PMMA, allowing for the selective removal of exposed areas by a chemical developer, making it a positive photoresist. PMMA's advantage is that it allows for extremely high resolution patterns to be made. Smooth PMMA surface can be easily nanostructured by treatment in oxygen radio-frequency plasma and nanostructured PMMA surface can be easily smoothed by vacuum ultraviolet (VUV) irradiation.

* PMMA is used as a shield to stop beta radiation emitted from radioisotopes.

* Small strips of PMMA are used as dosimeter devices during the gamma ray, Gamma Irradiation process. The optical properties of PMMA change as the gamma dose increases, and can be measured with a spectrophotometry, spectrophotometer.

* A black light, blacklight-reactive tattoo ink using PMMA micro-encapsulation, microcapsules has been developed.

* PMMA can be used as a dispersant for ceramic powders to stabilize colloidal suspensions in non-aqueous media. Due to its high viscosity upon dissolution, it can also be used as binder material for solution deposition processes, e.g. printing of solar cells.

* In the 1960s, luthier Dan Armstrong developed a line of electric guitars and basses whose bodies were made completely of acrylic. These instruments were marketed under the Ampeg brand. Ibanez and B.C. Rich have also made acrylic guitars.

* Ludwig-Musser makes a line of acrylic drums called Vistalites, well known as being used by Led Zeppelin drummer John Bonham.

* Artificial nails in the "acrylic" type often include PMMA powder.

* Some modern briar, and occasionally meerschaum, tobacco pipes sport stems made of Lucite.

* PMMA technology is utilized in roofing and waterproofing applications. By incorporating a polyester fleece sandwiched between two layers of catalyst-activated PMMA resin, a fully reinforced liquid membrane is created ''in situ''.

* PMMA is a widely used material to create deal toys and tombstone (financial industry), financial tombstones.

* PMMA is used by the Sailor Pen Company of Kure, Hiroshima, Kure, Japan in their standard models of goldnib (pen), -nib Fountain Pen, fountain pens, specifically as the cap and body material.

* PMMA, in the commercial form Technovit 7200 is used vastly in the medical field. It is used for plastic histology, electron microscopy, as well as many more uses.

* PMMA has been used to create ultra-white opaque membranes that are flexible and switch appearance to transparent when wet.

* Acrylic is used in tanning beds as the transparent surface that separates the occupant from the tanning bulbs while tanning. The type of acrylic used in tanning beds is most often formulated from a special type of polymethyl methacrylate, a compound that allows the passage of ultraviolet rays.

* Sheets of PMMA are commonly used in the sign industry to make flat cut out letters in thicknesses typically varying from . These letters may be used alone to represent a company's name and/or logo, or they may be a component of illuminated channel letters. Acrylic is also used extensively throughout the sign industry as a component of wall signs where it may be a backplate, painted on the surface or the backside, a faceplate with additional raised lettering or even photographic images printed directly to it, or a spacer to separate sign components.

* PMMA was used in Laserdisc optical media. (Compact Disc, CDs and DVDs use both acrylic and polycarbonate for impact resistance).

* It is used as a light guide for the backlights in TFT LCD, TFT-LCDs.

* Plastic optical fiber used for short-distance communication is made from PMMA, and perfluorinated PMMA, clad with fluorinated PMMA, in situations where its flexibility and cheaper installation costs outweigh its poor heat tolerance and higher attenuation versus glass fiber.

* PMMA, in a purified form, is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.

* In semiconductor research and industry, PMMA aids as a resist (semiconductor fabrication), resist in the electron beam lithography process. A solution consisting of the polymer in a solvent is used to spin coating, spin coat silicon and other semiconducting and semi-insulating wafers with a thin film. Patterns on this can be made by an electron beam (using an electron microscope), deep UV light (shorter wavelength than the standard photolithography process), or X-rays. Exposure to these creates chain scission or (de-cross-linking) within the PMMA, allowing for the selective removal of exposed areas by a chemical developer, making it a positive photoresist. PMMA's advantage is that it allows for extremely high resolution patterns to be made. Smooth PMMA surface can be easily nanostructured by treatment in oxygen radio-frequency plasma and nanostructured PMMA surface can be easily smoothed by vacuum ultraviolet (VUV) irradiation.

* PMMA is used as a shield to stop beta radiation emitted from radioisotopes.

* Small strips of PMMA are used as dosimeter devices during the gamma ray, Gamma Irradiation process. The optical properties of PMMA change as the gamma dose increases, and can be measured with a spectrophotometry, spectrophotometer.

* A black light, blacklight-reactive tattoo ink using PMMA micro-encapsulation, microcapsules has been developed.

* PMMA can be used as a dispersant for ceramic powders to stabilize colloidal suspensions in non-aqueous media. Due to its high viscosity upon dissolution, it can also be used as binder material for solution deposition processes, e.g. printing of solar cells.

* In the 1960s, luthier Dan Armstrong developed a line of electric guitars and basses whose bodies were made completely of acrylic. These instruments were marketed under the Ampeg brand. Ibanez and B.C. Rich have also made acrylic guitars.

* Ludwig-Musser makes a line of acrylic drums called Vistalites, well known as being used by Led Zeppelin drummer John Bonham.

* Artificial nails in the "acrylic" type often include PMMA powder.

* Some modern briar, and occasionally meerschaum, tobacco pipes sport stems made of Lucite.

* PMMA technology is utilized in roofing and waterproofing applications. By incorporating a polyester fleece sandwiched between two layers of catalyst-activated PMMA resin, a fully reinforced liquid membrane is created ''in situ''.

* PMMA is a widely used material to create deal toys and tombstone (financial industry), financial tombstones.

* PMMA is used by the Sailor Pen Company of Kure, Hiroshima, Kure, Japan in their standard models of goldnib (pen), -nib Fountain Pen, fountain pens, specifically as the cap and body material.

Perspex Technical Properties

Perspex Material Safety Data Sheet (MSDS)

{{Authority control Acrylate polymers Amorphous solids Biomaterials Commodity chemicals Dental materials Dielectrics Engineering plastic German inventions Optical materials Plastics Thermoplastics Transparent materials

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastic

Engineering plastics are a group of plastic materials that have better mechanical and/or thermal properties than the more widely used commodity plastics (such as polystyrene, PVC, polypropylene and polyethylene).

Being more expensive than sta ...

s. It is a transparent

Transparency, transparence or transparent most often refer to:

* Transparency (optics), the physical property of allowing the transmission of light through a material

They may also refer to:

Literal uses

* Transparency (photography), a still, ...

thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, Astariglas, Lucite, Perclax, and Perspex, among several others ( see below). This plastic is often used in sheet form as a lightweight or shatter-resistant alternative to glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of ...

. It can also be used as a casting resin, in inks and coatings, and for many other purposes.

Although not a type of familiar silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

-based glass, the substance, like many thermoplastics, is often technically classified as a type of glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of ...

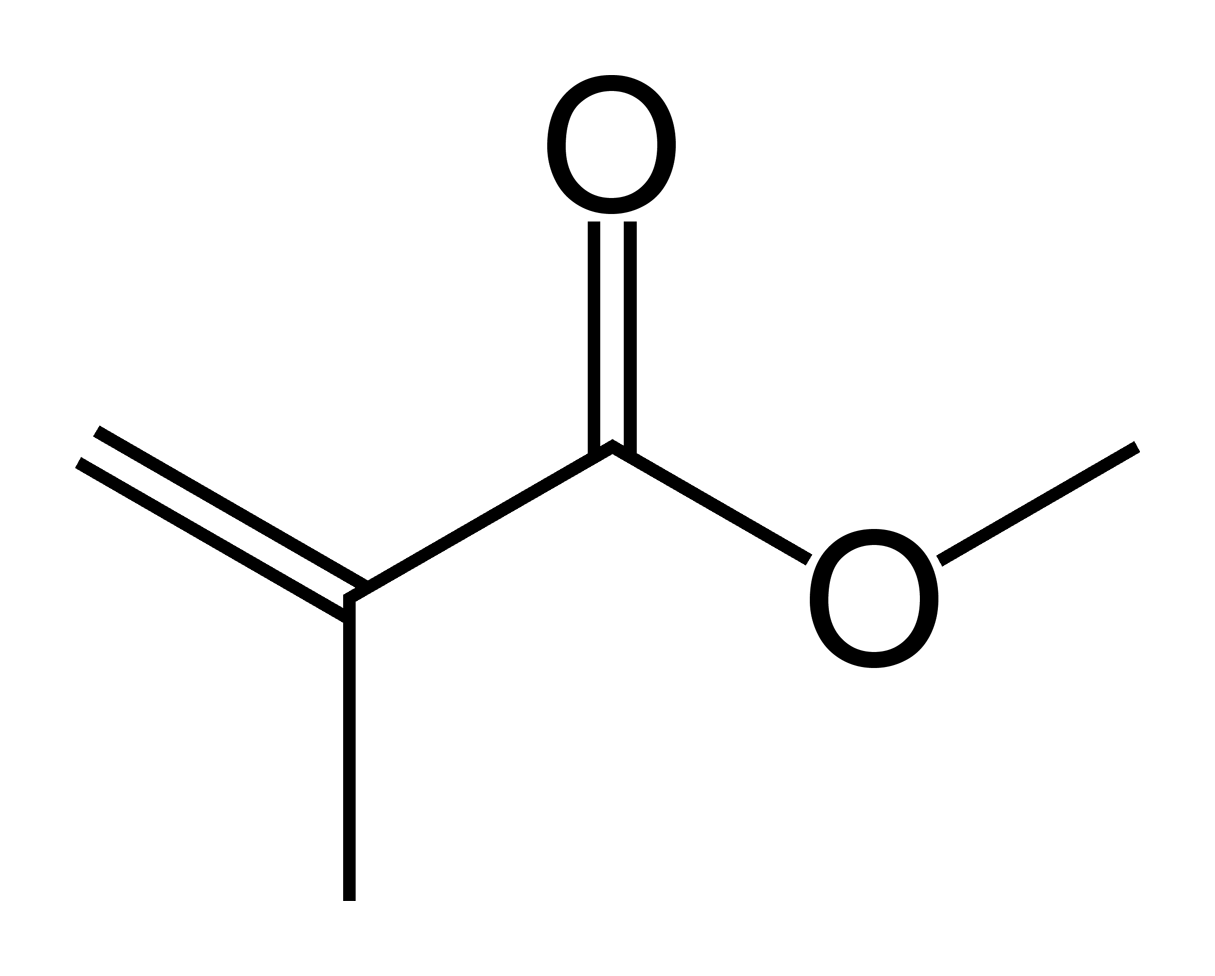

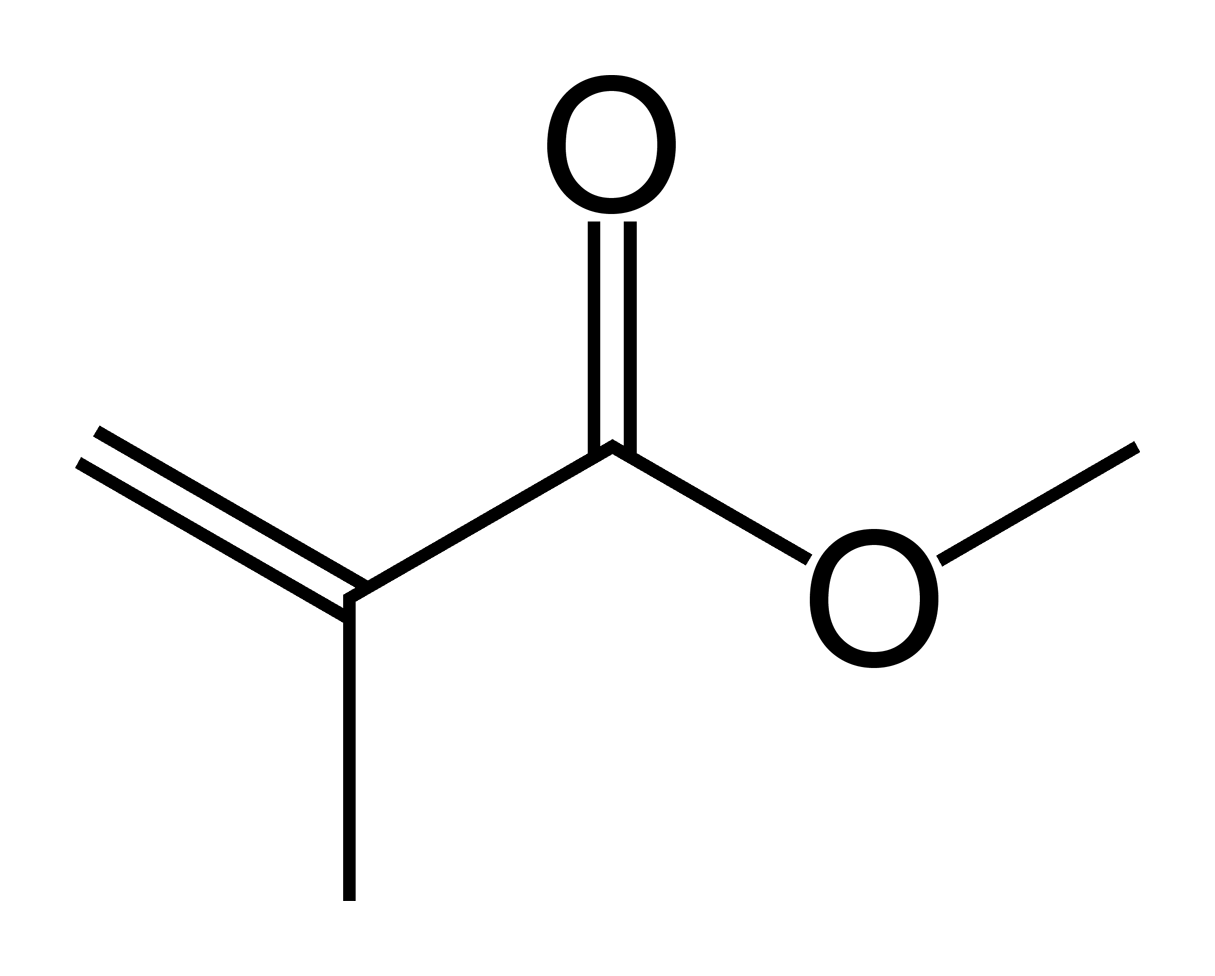

, in that it is a non-crystalline vitreous substance—hence its occasional historic designation as ''acrylic glass''. Chemically, it is the synthetic polymer of methyl methacrylate

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, the methyl ester of methacrylic acid (MAA), is a monomer produced on a large scale for the production of poly(methyl methacrylate) (PMMA ...

. It was developed in 1928 in several different laboratories by many chemists, such as William Chalmers, Otto Röhm

Otto Karl Julius Röhm (; 14 March 1876, Öhringen, Germany – 17 September 1939, Berlin) was one of the founders and a longtime president of the ''Röhm und Haas'' chemical company which became later in the USA the Rohm and Haas (today '' Dow ...

, and Walter Bauer, and first brought to market in 1933 by German ''Röhm & Haas AG'' (as of January 2019, part of Evonik Industries

Evonik Industries AG is a stock-listed German specialty chemicals company headquartered in Essen, North Rhine-Westphalia, Germany. It is the second largest chemicals company in Germany, and one of the largest specialty chemicals companies in the ...

) and its partner and former U.S. affiliate Rohm and Haas Company under the trademark

A trademark (also written trade mark or trade-mark) is a type of intellectual property consisting of a recognizable sign, design, or expression that identifies products or services from a particular source and distinguishes them from others ...

Plexiglas.

PMMA is an economical alternative to polycarbonate

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily work ...

(PC) when tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials t ...

, flexural strength

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most freque ...

, transparency, polishability, and UV tolerance are more important than impact strength

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.bisphenol-A

Bisphenol A (BPA) is a chemical compound primarily used in the manufacturing of various plastics. It is a colourless solid which is soluble in most common organic solvents, but has very poor solubility in water. BPA is produced on an industrial s ...

subunits found in polycarbonate and is a far better choice for laser cutting. It is often preferred because of its moderate properties, easy handling and processing, and low cost. Non-modified PMMA behaves in a brittle manner when under load, especially under an impact force

In mechanics, an impact is a high force or shock applied over a short time period when two or more bodies collide. Such a force or acceleration usually has a greater effect than a lower force applied over a proportionally longer period. Th ...

, and is more prone to scratching than conventional inorganic glass, but modified PMMA is sometimes able to achieve high scratch and impact resistance.

History

The first acrylic acid was created in 1843.Methacrylic acid

Methacrylic acid, abbreviated MAA, is an organic compound. This colorless, viscous liquid is a carboxylic acid with an acrid unpleasant odor. It is soluble in warm water and miscible with most organic solvents. Methacrylic acid is produced indu ...

, derived from acrylic acid

Acrylic acid (IUPAC: propenoic acid) is an organic compound with the formula CH2=CHCOOH. It is the simplest unsaturated carboxylic acid, consisting of a vinyl group connected directly to a carboxylic acid terminus. This colorless liquid has a ...

, was formulated in 1865. The reaction between methacrylic acid and methanol

Methanol (also called methyl alcohol and wood spirit, amongst other names) is an organic chemical and the simplest aliphatic alcohol, with the formula C H3 O H (a methyl group linked to a hydroxyl group, often abbreviated as MeOH). It is a ...

results in the ester methyl methacrylate. Polymethyl methacrylate was discovered in the early 1930s by British chemists Rowland Hill and John Crawford at Imperial Chemical Industries

Imperial Chemical Industries (ICI) was a British chemical company. It was, for much of its history, the largest manufacturer in Britain.

It was formed by the merger of four leading British chemical companies in 1926.

Its headquarters were at M ...

(ICI) in the United Kingdom. ICI registered the product under the trademark Perspex. About the same time, chemist and industrialist Otto Röhm

Otto Karl Julius Röhm (; 14 March 1876, Öhringen, Germany – 17 September 1939, Berlin) was one of the founders and a longtime president of the ''Röhm und Haas'' chemical company which became later in the USA the Rohm and Haas (today '' Dow ...

of Röhm and Haas AG in Germany attempted to produce safety glass by polymerizing methyl methacrylate between two layers of glass. The polymer separated from the glass as a clear plastic sheet, which Röhm gave the trademarked name Plexiglas in 1933. Both Perspex and Plexiglas were commercialized in the late 1930s. In the United States, E.I. du Pont de Nemours & Company (now DuPont Company) subsequently introduced its own product under the trademark Lucite. In 1936 ICI Acrylics (now Lucite International) began the first commercially viable production of acrylic safety glass. During World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposin ...

both Allied and Axis forces used acrylic glass for submarine periscopes and aircraft windscreen, canopies, and gun turrets. Aeroplane pilots whose eyes were damaged by flying shards of PMMA fared much better than those injured by standard glass, demonstrating better compatibility between human tissue and PMMA than glass. Civilian applications followed after the war.

Names

Common orthographic stylings include ''polymethyl methacrylate'' and ''polymethylmethacrylate''. The full IUPAC chemical name is poly(methyl 2-methylpropenoate). (It is a common mistake to use "an" instead of "en".) Although PMMA is often called simply "acrylic", ''acrylic

Acrylic may refer to:

Chemicals and materials

* Acrylic acid, the simplest acrylic compound

* Acrylate polymer, a group of polymers (plastics) noted for transparency and elasticity

* Acrylic resin, a group of related thermoplastic or thermosett ...

'' can also refer to other polymers or copolymers containing polyacrylonitrile

Polyacrylonitrile (PAN), also known as polyvinyl cyanide and Creslan 61, is a synthetic, semicrystalline organic polymer resin, with the linear formula (C3H3N)n. Though it is thermoplastic, it does not melt under normal conditions. It degrades bef ...

. Notable trade names and brands include Acrylite, Lucite, PerClax, R-Cast, Plexiglas, Optix, Perspex, Oroglas, Altuglas, Cyrolite, Astariglas, Cho Chen, Sumipex, and Crystallite.

Synthesis

PMMA is routinely produced byemulsion polymerization Emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water, monomer, and surfactant. The most common type of emulsion polymerization is an oil-in-water emulsion, in which droplets of monomer ...

, solution polymerization

Solution polymerization is a method of industrial polymerization. In this procedure, a monomer is dissolved in a non-reactive solvent that contains a catalyst or initiator.

The reaction results in a polymer which is also soluble in the chosen solv ...

, and bulk polymerization

Bulk polymerization or mass polymerization is carried out by adding a soluble radical initiator to pure monomer in liquid state. The initiator should dissolve in the monomer. The reaction is initiated by heating or exposing to radiation. As the rea ...

. Generally, radical initiation is used (including living polymerization

In polymer chemistry, living polymerization is a form of chain growth polymerization where the ability of a growing polymer chain to terminate has been removed. This can be accomplished in a variety of ways. Chain termination and chain transfer ...

methods), but anionic polymerization of PMMA can also be performed. To produce of PMMA, about of petroleum

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name ''petroleum'' covers both naturally occurring unprocessed crud ...

is needed. PMMA produced by radical polymerization

In polymer chemistry, free-radical polymerization (FRP) is a method of polymerization by which a polymer forms by the successive addition of free-radical building blocks (repeat units). Free radicals can be formed by a number of different mechanis ...

(all commercial PMMA) is atactic

Tacticity (from el, τακτικός, taktikos, "relating to arrangement or order") is the relative stereochemistry of adjacent chiral centers within a macromolecule. The practical significance of tacticity rests on the effects on the physical p ...

and completely amorphous.

Processing

Theglass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rubb ...

(''Tg'') of atactic

Tacticity (from el, τακτικός, taktikos, "relating to arrangement or order") is the relative stereochemistry of adjacent chiral centers within a macromolecule. The practical significance of tacticity rests on the effects on the physical p ...

PMMA is . The ''Tg'' values of commercial grades of PMMA range from ; the range is so wide because of the vast number of commercial compositions which are copolymers with co-monomers other than methyl methacrylate. PMMA is thus an organic glass at room temperature; i.e., it is below its ''Tg''. The forming temperature starts at the glass transition temperature and goes up from there. All common molding processes may be used, including injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

, compression molding

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material int ...

, and extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex c ...

. The highest quality PMMA sheets are produced by cell casting

Cell casting is a method used for creating poly(methyl methacrylate) (PMMA) sheets. Liquid monomer is poured between two flat sheets of toughened glass sealed with a rubber gasket and heated for polymerization. Because the glass sheets may contain ...

, but in this case, the polymerization and molding steps occur concurrently. The strength of the material is higher than molding grades owing to its extremely high molecular mass

The molecular mass (''m'') is the mass of a given molecule: it is measured in daltons (Da or u). Different molecules of the same compound may have different molecular masses because they contain different isotopes of an element. The related quanti ...

. Rubber toughening Rubber toughening is a process in which rubber nanoparticles are interspersed within a polymer matrix to increase the mechanical robustness, or toughness, of the material. By "toughening" a polymer it is meant that the ability of the polymeric subst ...

has been used to increase the toughness of PMMA to overcome its brittle behavior in response to applied loads.

Handling, cutting, and joining

PMMA can be joined usingcyanoacrylate

Cyanoacrylates are a family of strong fast-acting adhesives with industrial, medical, and household uses. They are derived from ethyl cyanoacrylate and related esters. The cyanoacrylate group in the monomer rapidly polymerizes in the presence ...

cement (commonly known as superglue

Cyanoacrylates are a family of strong fast-acting adhesives with industrial, medical, and household uses. They are derived from ethyl cyanoacrylate and related esters. The cyanoacrylate group in the monomer rapidly polymerizes in the presence ...

), with heat (welding), or by using chlorinated solvents such as dichloromethane

Dichloromethane (DCM or methylene chloride, methylene bichloride) is an organochlorine compound with the formula . This colorless, volatile liquid with a chloroform-like, sweet odour is widely used as a solvent. Although it is not miscible with ...

or trichloromethane

Chloroform, or trichloromethane, is an organic compound with formula C H Cl3 and a common organic solvent. It is a colorless, strong-smelling, dense liquid produced on a large scale as a precursor to PTFE. It is also a precursor to various ref ...

(chloroform) to dissolve the plastic at the joint, which then fuses and sets, forming an almost invisible weld. Scratches may easily be removed by polishing or by heating the surface of the material.

Laser cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutt ...

may be used to form intricate designs from PMMA sheets. PMMA vaporizes to gaseous compounds (including its monomers) upon laser cutting, so a very clean cut is made, and cutting is performed very easily. However, the pulsed lasercutting introduces high internal stresses along the cut edge, which on exposure to solvents produce undesirable "stress-crazing" at the cut edge and several millimetres deep. Even ammonium-based glass-cleaner and almost everything short of soap-and-water produces similar undesirable crazing, sometimes over the entire surface of the cut parts, at great distances from the stressed edge. Annealing the PMMA sheet/parts is therefore an obligatory post-processing step when intending to chemically bond lasercut parts together.

In the majority of applications, it will not shatter. Rather, it breaks into large dull pieces. Since PMMA is softer and more easily scratched than glass, scratch-resistant coatings are often added to PMMA sheets to protect it (as well as possible other functions).

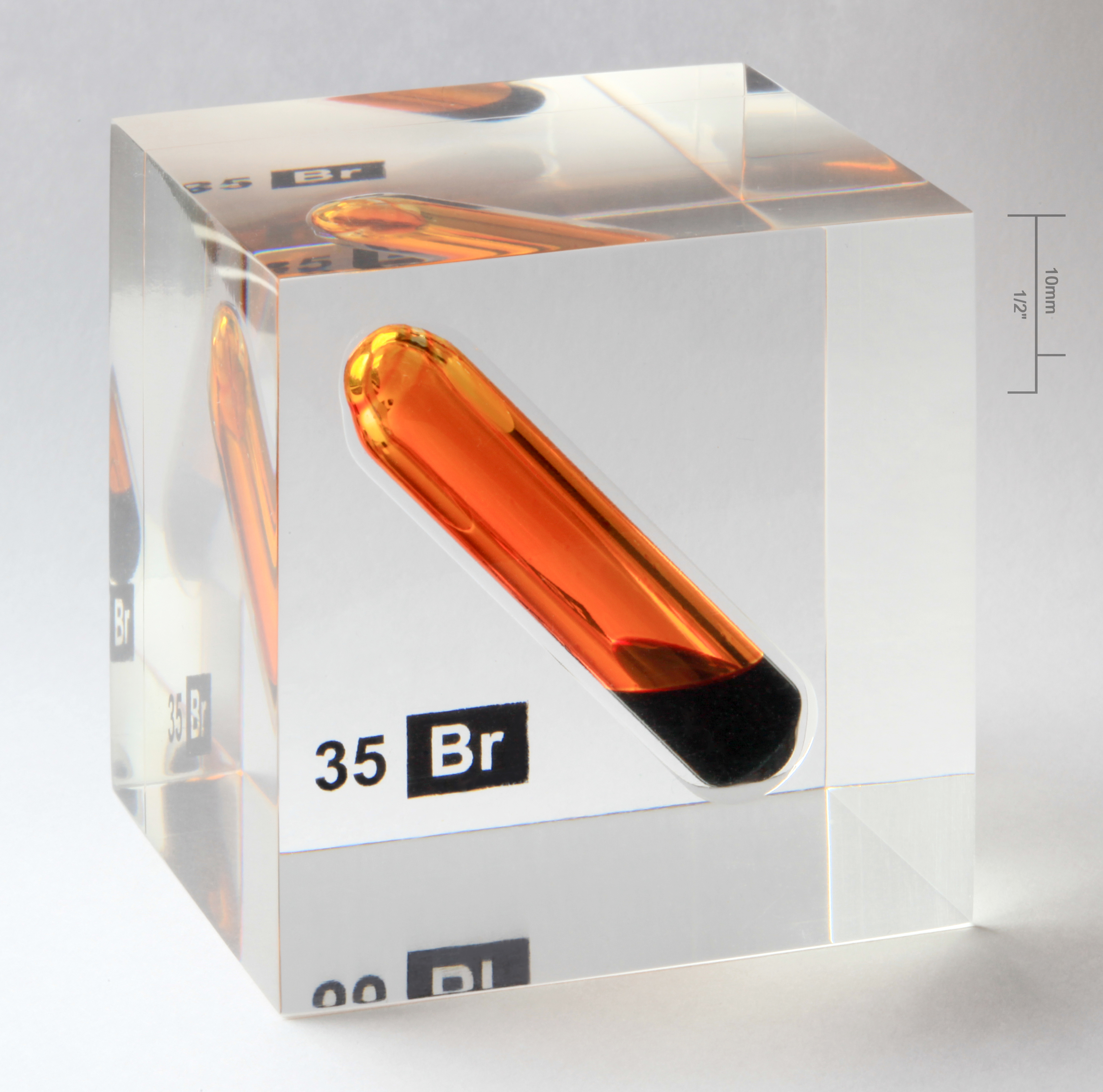

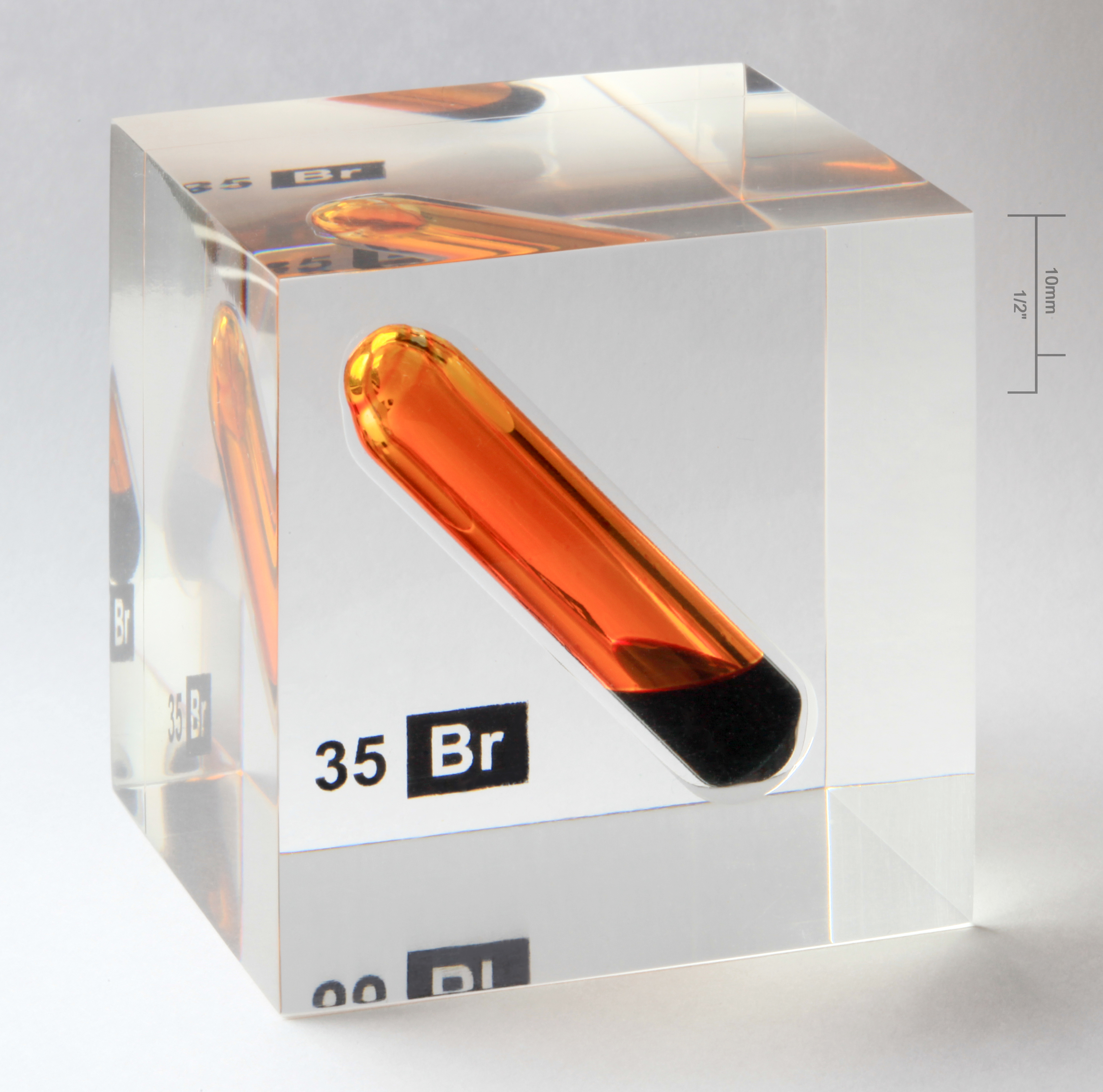

Acrylate resin casting

Methyl methacrylate

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colorless liquid, the methyl ester of methacrylic acid (MAA), is a monomer produced on a large scale for the production of poly(methyl methacrylate) (PMMA ...

"synthetic resin

Synthetic resins are industrially produced resins, typically viscous substances that convert into rigid polymers by the process of curing. In order to undergo curing, resins typically contain reactive end groups, such as acrylates or epoxides. ...

" for casting (simply the bulk liquid chemical) may be used in conjunction with a polymerization catalyst such as methyl ethyl ketone peroxide (MEKP), to produce hardened transparent PMMA in any shape, from a mold. Objects like insects or coins, or even dangerous chemicals in breakable quartz ampules, may be embedded in such "cast" blocks, for display and safe handling.

Properties

PMMA is a strong, tough, and lightweight material. It has a density of 1.17–1.20 g/cm3, which is less than half that of glass.Polymethylmethacrylate (PMMA, Acrylic)

PMMA is a strong, tough, and lightweight material. It has a density of 1.17–1.20 g/cm3, which is less than half that of glass.Polymethylmethacrylate (PMMA, Acrylic). Makeitfrom.com. Retrieved 2015-03-23. It also has good impact strength, higher than both glass and polystyrene; however, PMMA's impact strength is still significantly lower than polycarbonate and some engineered polymers. PMMA ignites at and combustion, burns, forming carbon dioxide, water, carbon monoxide, and low-molecular-weight compounds, including formaldehyde. PMMA transmittance, transmits up to 92% of visible light (3 mm thickness), and gives a reflection of about 4% from each of its surfaces due to its refractive index (1.4905 at 589.3 nm).Refractive index and related constants – Poly(methyl methacrylate) (PMMA, Acrylic glass)

. Refractiveindex.info. Retrieved 2014-10-27. It filters ultraviolet (UV) light at wavelengths below about 300 nanometre, nm (similar to ordinary window glass). Some manufacturers add coatings or additives to PMMA to improve absorption in the 300–400 nm range. PMMA passes infrared light of up to 2,800 nm and blocks IR of longer wavelengths up to 25,000 nm. Colored PMMA varieties allow specific IR wavelengths to pass while blocking visible spectrum, visible light (for remote control or heat sensor applications, for example). PMMA swells and dissolves in many organic solvents; it also has poor resistance to many other chemicals due to its easily hydrolysis, hydrolyzed ester groups. Nevertheless, its environmental stability is superior to most other plastics such as polystyrene and polyethylene, and therefore it is often the material of choice for outdoor applications. PMMA has a maximum water absorption ratio of 0.3–0.4% by weight.DATA TABLE FOR: Polymers: Commodity Polymers: PMMA

. Matbase.com. Retrieved 2012-05-09. Tensile strength decreases with increased water absorption. Its coefficient of thermal expansion is relatively high at (5–10)×10−5 °C−1.

Modification of properties

Pure poly(methyl methacrylate) homopolymer is rarely sold as an end product, since it is not optimized for most applications. Rather, modified formulations with varying amounts of other comonomers, additives, and fillers are created for uses where specific properties are required. For example, * A small amount of acrylate comonomers are routinely used in PMMA grades destined for heat processing, since this stabilizes the polymer to depolymerization ("unzipping") during processing. * Comonomers such as butyl acrylate are often added to improve impact strength. * Comonomers such as methacrylic acid can be added to increase the glass transition temperature of the polymer for higher temperature use such as in lighting applications. * Plasticizers may be added to improve processing properties, lower the glass transition temperature, improve impact properties, and improve mechanical properties such as elastic modulus * Dyes may be added to give color for decorative applications, or to protect against (or filter) UV light. * Filler (materials), Fillers may be added to improve cost-effectiveness.Poly(methyl acrylate)

The polymer of methyl acrylate, PMA or poly(methyl acrylate), is similar to poly(methyl methacrylate), except for the lack of methyl groups on the backbone carbon chain. PMA is a soft white rubbery material that is softer than PMMA because its long polymer chains are thinner and smoother and can more easily slide past each other.Uses

Being transparent and durable, PMMA is a versatile material and has been used in a wide range of fields and applications such as rear-lights and instrument clusters for vehicles, appliances, and lenses for glasses. PMMA in the form of sheets affords to shatter resistant panels for building windows, skylights, bulletproof security barriers, signs & displays, sanitary ware (bathtubs), LCD screens, furniture and many other applications. It is also used for coating polymers based on MMA provides outstanding stability against environmental conditions with reduced emission of VOC. Methacrylate polymers are used extensively in medical and dental applications where purity and stability are critical to performance.Transparent glass substitute

* PMMA is commonly used for constructing residential and commercial aquariums. Designers started building large aquariums when poly(methyl methacrylate) could be used. It is less often used in other building types due to incidents such as the Summerland disaster.

* PMMA is used for viewing ports and even complete pressure hulls of submersibles, such as the Alicia (submarine), ''Alicia'' submarine's viewing sphere and the window of the bathyscaphe Trieste.

* PMMA is used in the lenses of exterior lights of automobiles.

* Spectator protection in ice hockey rinks is made from PMMA.

* Historically, PMMA was an important improvement in the design of aircraft windows, making possible such designs as the bombardier's transparent nose compartment in the Boeing B-17 Flying Fortress. Modern aircraft transparencies often use stretched acrylic plies.

* Police vehicles for riot control often have the regular glass replaced with PMMA to protect the occupants from thrown objects.

* PMMA is an important material in the making of certain lighthouse lenses.

* PMMA was used for the roofing of the compound in the Olympiapark, Munich, Olympic Park for the 1972 Summer Olympics in Munich. It enabled a light and translucent construction of the structure.

* PMMA (under the brand name "Lucite") was used for the ceiling of the Reliant Astrodome, Houston Astrodome.

* PMMA is commonly used for constructing residential and commercial aquariums. Designers started building large aquariums when poly(methyl methacrylate) could be used. It is less often used in other building types due to incidents such as the Summerland disaster.

* PMMA is used for viewing ports and even complete pressure hulls of submersibles, such as the Alicia (submarine), ''Alicia'' submarine's viewing sphere and the window of the bathyscaphe Trieste.

* PMMA is used in the lenses of exterior lights of automobiles.

* Spectator protection in ice hockey rinks is made from PMMA.

* Historically, PMMA was an important improvement in the design of aircraft windows, making possible such designs as the bombardier's transparent nose compartment in the Boeing B-17 Flying Fortress. Modern aircraft transparencies often use stretched acrylic plies.

* Police vehicles for riot control often have the regular glass replaced with PMMA to protect the occupants from thrown objects.

* PMMA is an important material in the making of certain lighthouse lenses.

* PMMA was used for the roofing of the compound in the Olympiapark, Munich, Olympic Park for the 1972 Summer Olympics in Munich. It enabled a light and translucent construction of the structure.

* PMMA (under the brand name "Lucite") was used for the ceiling of the Reliant Astrodome, Houston Astrodome.

Daylight redirection

* Laser cut acrylic panels have been used to redirect sunlight into a light tube#Light tube with reflective material, light pipe or tubular skylight and, from there, to spread it into a room. Their developers Veronica Garcia Hansen, Ken Yeang, and Ian Edmonds were awarded the Far Eastern Economic Review#Awards presented by FEER, Far East Economic Review Innovation Award in bronze for this technology in 2003. * Attenuation being quite strong for distances over one meter (more than 90% intensity loss for a 3000 K source), acrylic broadband light guides are then dedicated mostly to decorative uses. * Pairs of acrylic sheets with a layer of microreplicated prisms between the sheets can have reflective and refractive properties that let them redirect part of incoming sunlight in dependence on its angle of incidence (optics), angle of incidence. Such panels act as miniature architectural light shelf, light shelves. Such panels have been commercialized for purposes of daylighting, to be used as a window or a canopy (building), canopy such that sunlight descending from the sky is directed to the ceiling or into the room rather than to the floor. This can lead to a higher illumination of the back part of a room, in particular when combined with a white ceiling, while having a slight impact on the view to the outside compared to normal glazing.Medical technologies and implants

* PMMA has a good degree of compatibility with human tissue (biology), tissue, and it is used in the manufacture of rigid intraocular lenses which are implanted in the human eye, eye when the original lens has been removed in the treatment of cataracts. This compatibility was discovered by the English ophthalmologist Harold Ridley (ophthalmologist), Harold Ridley in WWII RAF pilots, whose eyes had been riddled with PMMA splinters coming from the side windows of their Supermarine Spitfire fighters – the plastic scarcely caused any rejection, compared to glass splinters coming from aircraft such as the Hawker Hurricane. Ridley had a lens manufactured by the Rayner company (Brighton & Hove, East Sussex) made from Perspex polymerised by ICI. On 29 November 1949 at St Thomas' Hospital, London, Ridley implanted the first intraocular lens at St Thomas's Hospital in London. In particular, acrylic-type contact lenses are useful for cataract surgery in patients that have recurrent ocular inflammation (uveitis), as acrylic material induces less inflammation. * Glasses, Eyeglass lenses are commonly made from PMMA. * Historically, hard contact lenses were frequently made of this material. Soft contact lenses are often made of a related polymer, where acrylate monomers containing one or more hydroxyl, hydroxyl groups make them hydrophile, hydrophilic. * In orthopedic surgery, PMMA bone cement is used to affix implants and to remodel lost bone. It is supplied as a powder with liquid methyl methacrylate (MMA). Although PMMA is biologically compatible, MMA is considered to be an irritant and a possible carcinogen. PMMA has also been linked to cardiopulmonary resuscitation, cardiopulmonary events in the operating room due to hypotension. Bone cement acts like a grout and not so much like a glue in arthroplasty. Although sticky, it does not bond to either the bone or the implant; rather, it primarily fills the spaces between the prosthesis and the bone preventing motion. A disadvantage of this bone cement is that it heats up to while setting that may cause thermal necrosis of neighboring tissue. A careful balance of initiators and monomers is needed to reduce the rate of polymerization, and thus the heat generated. * In plastic surgery, cosmetic surgery, tiny PMMA microspheres suspended in some biological fluid are injected as a soft-tissue filler under the skin to reduce wrinkles or scars permanently. PMMA as a soft-tissue filler was widely used in the beginning of the century to restore volume in patients with HIV-related facial wasting. PMMA is used illegally to shape muscles by some bodybuilding, bodybuilders. * Plombage is an outdated treatment of tuberculosis where the pleural space around an infected lung was filled with PMMA balls, in order to compress and collapse the affected lung. * Emerging biotechnology and medical research, biomedical research use PMMA to create microfluidics, microfluidic lab-on-a-chip devices, which require 100 micrometre-wide geometries for routing liquids. These small geometries are amenable to using PMMA in a biochip fabrication process and offers moderate biocompatibility. * Bioprocess chromatography columns use cast acrylic tubes as an alternative to glass and stainless steel. These are pressure rated and satisfy stringent requirements of materials for biocompatibility, toxicity, and extractables.Uses in dentistry

Due to its aforementioned biocompatibility, poly(methyl methacrylate) is a commonly used material in modern dentistry, particularly in the fabrication of dental prosthetics, artificial teeth, and orthodontic appliances. ; Acrylic prosthetic construction: Pre-polymerized, powdered PMMA spheres are mixed with a Methyl Methacrylate liquid monomer, Benzoyl Peroxide (initiator), and NN-Dimethyl-P-Toluidine (accelerator), and placed under heat and pressure to produce a hardened polymerized PMMA structure. Through the use of injection molding techniques, wax based designs with artificial teeth set in predetermined positions built on gypsum stone models of patients' mouths can be converted into functional prosthetics used to replace missing dentition. PMMA polymer and methyl methacrylate monomer mix is then injected into a flask containing a gypsum mold of the previously designed prosthesis, and placed under heat to initiate polymerization process. Pressure is used during the curing process to minimize polymerization shrinkage, ensuring an accurate fit of the prosthesis. Though other methods of polymerizing PMMA for prosthetic fabrication exist, such as chemical and microwave resin activation, the previously described heat-activated resin polymerization technique is the most commonly used due to its cost effectiveness and minimal polymerization shrinkage. ; Artificial teeth: While denture teeth can be made of several different materials, PMMA is a material of choice for the manufacturing of artificial teeth used in dental prosthetics. Mechanical properties of the material allow for heightened control of aesthetics, easy surface adjustments, decreased risk of fracture when in function in the oral cavity, and minimal wear against opposing teeth. Additionally, since the bases of dental prosthetics are often constructed using PMMA, adherence of PMMA denture teeth to PMMA denture bases is unparalleled, leading to the construction of a strong and durable prosthetic.Artistic and aesthetic uses

* Acrylic paint essentially consists of PMMA suspended in water; however since PMMA is hydrophobe, hydrophobic, a substance with both hydrophobic and hydrophilic groups needs to be added to facilitate the suspension (chemistry), suspension.

* Modern furniture makers, especially in the 1960s and 1970s, seeking to give their products a space age aesthetic, incorporated Lucite and other PMMA products into their designs, especially office chairs. Many other products (for example, guitars) are sometimes made with acrylic glass to make the commonly opaque objects translucent.

* Perspex has been used as a surface to paint on, for example by Salvador Dalí.

* Diasec is a process which uses acrylic glass as a substitute for normal glass in picture frames. This is done for its relatively low cost, light weight, shatter-resistance, aesthetics and because it can be ordered in larger sizes than standard picture framing glass.

* As early as 1939, Los Angeles-based Dutch sculptor Jan de Swart, Jan De Swart experimented with samples of Lucite sent to him by DuPont; De Swart created tools to work the Lucite for sculpture and mixed chemicals to bring about certain effects of color and refraction.

* From approximately the 1960s onward, sculptors and glass artists such as Jan Kubíček, Leroy Lamis, and Frederick Hart (sculptor), Frederick Hart began using acrylics, especially taking advantage of the material's flexibility, light weight, cost and its capacity to refract and filter light.

* In the 1950s and 1960s, Lucite was an extremely popular material for jewelry, with several companies specialized in creating high-quality pieces from this material. Lucite beads and ornaments are still sold by jewelry suppliers.

* Acrylic Sheets are produced in dozens of standard colors, most commonly sold using color numbers developed by Rohm & Haas in the 1950s.

* Acrylic paint essentially consists of PMMA suspended in water; however since PMMA is hydrophobe, hydrophobic, a substance with both hydrophobic and hydrophilic groups needs to be added to facilitate the suspension (chemistry), suspension.

* Modern furniture makers, especially in the 1960s and 1970s, seeking to give their products a space age aesthetic, incorporated Lucite and other PMMA products into their designs, especially office chairs. Many other products (for example, guitars) are sometimes made with acrylic glass to make the commonly opaque objects translucent.

* Perspex has been used as a surface to paint on, for example by Salvador Dalí.

* Diasec is a process which uses acrylic glass as a substitute for normal glass in picture frames. This is done for its relatively low cost, light weight, shatter-resistance, aesthetics and because it can be ordered in larger sizes than standard picture framing glass.

* As early as 1939, Los Angeles-based Dutch sculptor Jan de Swart, Jan De Swart experimented with samples of Lucite sent to him by DuPont; De Swart created tools to work the Lucite for sculpture and mixed chemicals to bring about certain effects of color and refraction.

* From approximately the 1960s onward, sculptors and glass artists such as Jan Kubíček, Leroy Lamis, and Frederick Hart (sculptor), Frederick Hart began using acrylics, especially taking advantage of the material's flexibility, light weight, cost and its capacity to refract and filter light.

* In the 1950s and 1960s, Lucite was an extremely popular material for jewelry, with several companies specialized in creating high-quality pieces from this material. Lucite beads and ornaments are still sold by jewelry suppliers.

* Acrylic Sheets are produced in dozens of standard colors, most commonly sold using color numbers developed by Rohm & Haas in the 1950s.

Other uses

* PMMA, in the commercial form Technovit 7200 is used vastly in the medical field. It is used for plastic histology, electron microscopy, as well as many more uses.

* PMMA has been used to create ultra-white opaque membranes that are flexible and switch appearance to transparent when wet.

* Acrylic is used in tanning beds as the transparent surface that separates the occupant from the tanning bulbs while tanning. The type of acrylic used in tanning beds is most often formulated from a special type of polymethyl methacrylate, a compound that allows the passage of ultraviolet rays.

* Sheets of PMMA are commonly used in the sign industry to make flat cut out letters in thicknesses typically varying from . These letters may be used alone to represent a company's name and/or logo, or they may be a component of illuminated channel letters. Acrylic is also used extensively throughout the sign industry as a component of wall signs where it may be a backplate, painted on the surface or the backside, a faceplate with additional raised lettering or even photographic images printed directly to it, or a spacer to separate sign components.

* PMMA was used in Laserdisc optical media. (Compact Disc, CDs and DVDs use both acrylic and polycarbonate for impact resistance).

* It is used as a light guide for the backlights in TFT LCD, TFT-LCDs.

* Plastic optical fiber used for short-distance communication is made from PMMA, and perfluorinated PMMA, clad with fluorinated PMMA, in situations where its flexibility and cheaper installation costs outweigh its poor heat tolerance and higher attenuation versus glass fiber.

* PMMA, in a purified form, is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.

* In semiconductor research and industry, PMMA aids as a resist (semiconductor fabrication), resist in the electron beam lithography process. A solution consisting of the polymer in a solvent is used to spin coating, spin coat silicon and other semiconducting and semi-insulating wafers with a thin film. Patterns on this can be made by an electron beam (using an electron microscope), deep UV light (shorter wavelength than the standard photolithography process), or X-rays. Exposure to these creates chain scission or (de-cross-linking) within the PMMA, allowing for the selective removal of exposed areas by a chemical developer, making it a positive photoresist. PMMA's advantage is that it allows for extremely high resolution patterns to be made. Smooth PMMA surface can be easily nanostructured by treatment in oxygen radio-frequency plasma and nanostructured PMMA surface can be easily smoothed by vacuum ultraviolet (VUV) irradiation.

* PMMA is used as a shield to stop beta radiation emitted from radioisotopes.

* Small strips of PMMA are used as dosimeter devices during the gamma ray, Gamma Irradiation process. The optical properties of PMMA change as the gamma dose increases, and can be measured with a spectrophotometry, spectrophotometer.

* A black light, blacklight-reactive tattoo ink using PMMA micro-encapsulation, microcapsules has been developed.

* PMMA can be used as a dispersant for ceramic powders to stabilize colloidal suspensions in non-aqueous media. Due to its high viscosity upon dissolution, it can also be used as binder material for solution deposition processes, e.g. printing of solar cells.

* In the 1960s, luthier Dan Armstrong developed a line of electric guitars and basses whose bodies were made completely of acrylic. These instruments were marketed under the Ampeg brand. Ibanez and B.C. Rich have also made acrylic guitars.

* Ludwig-Musser makes a line of acrylic drums called Vistalites, well known as being used by Led Zeppelin drummer John Bonham.

* Artificial nails in the "acrylic" type often include PMMA powder.

* Some modern briar, and occasionally meerschaum, tobacco pipes sport stems made of Lucite.

* PMMA technology is utilized in roofing and waterproofing applications. By incorporating a polyester fleece sandwiched between two layers of catalyst-activated PMMA resin, a fully reinforced liquid membrane is created ''in situ''.

* PMMA is a widely used material to create deal toys and tombstone (financial industry), financial tombstones.

* PMMA is used by the Sailor Pen Company of Kure, Hiroshima, Kure, Japan in their standard models of goldnib (pen), -nib Fountain Pen, fountain pens, specifically as the cap and body material.

* PMMA, in the commercial form Technovit 7200 is used vastly in the medical field. It is used for plastic histology, electron microscopy, as well as many more uses.

* PMMA has been used to create ultra-white opaque membranes that are flexible and switch appearance to transparent when wet.

* Acrylic is used in tanning beds as the transparent surface that separates the occupant from the tanning bulbs while tanning. The type of acrylic used in tanning beds is most often formulated from a special type of polymethyl methacrylate, a compound that allows the passage of ultraviolet rays.

* Sheets of PMMA are commonly used in the sign industry to make flat cut out letters in thicknesses typically varying from . These letters may be used alone to represent a company's name and/or logo, or they may be a component of illuminated channel letters. Acrylic is also used extensively throughout the sign industry as a component of wall signs where it may be a backplate, painted on the surface or the backside, a faceplate with additional raised lettering or even photographic images printed directly to it, or a spacer to separate sign components.

* PMMA was used in Laserdisc optical media. (Compact Disc, CDs and DVDs use both acrylic and polycarbonate for impact resistance).

* It is used as a light guide for the backlights in TFT LCD, TFT-LCDs.

* Plastic optical fiber used for short-distance communication is made from PMMA, and perfluorinated PMMA, clad with fluorinated PMMA, in situations where its flexibility and cheaper installation costs outweigh its poor heat tolerance and higher attenuation versus glass fiber.

* PMMA, in a purified form, is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.

* In semiconductor research and industry, PMMA aids as a resist (semiconductor fabrication), resist in the electron beam lithography process. A solution consisting of the polymer in a solvent is used to spin coating, spin coat silicon and other semiconducting and semi-insulating wafers with a thin film. Patterns on this can be made by an electron beam (using an electron microscope), deep UV light (shorter wavelength than the standard photolithography process), or X-rays. Exposure to these creates chain scission or (de-cross-linking) within the PMMA, allowing for the selective removal of exposed areas by a chemical developer, making it a positive photoresist. PMMA's advantage is that it allows for extremely high resolution patterns to be made. Smooth PMMA surface can be easily nanostructured by treatment in oxygen radio-frequency plasma and nanostructured PMMA surface can be easily smoothed by vacuum ultraviolet (VUV) irradiation.

* PMMA is used as a shield to stop beta radiation emitted from radioisotopes.

* Small strips of PMMA are used as dosimeter devices during the gamma ray, Gamma Irradiation process. The optical properties of PMMA change as the gamma dose increases, and can be measured with a spectrophotometry, spectrophotometer.

* A black light, blacklight-reactive tattoo ink using PMMA micro-encapsulation, microcapsules has been developed.

* PMMA can be used as a dispersant for ceramic powders to stabilize colloidal suspensions in non-aqueous media. Due to its high viscosity upon dissolution, it can also be used as binder material for solution deposition processes, e.g. printing of solar cells.

* In the 1960s, luthier Dan Armstrong developed a line of electric guitars and basses whose bodies were made completely of acrylic. These instruments were marketed under the Ampeg brand. Ibanez and B.C. Rich have also made acrylic guitars.

* Ludwig-Musser makes a line of acrylic drums called Vistalites, well known as being used by Led Zeppelin drummer John Bonham.

* Artificial nails in the "acrylic" type often include PMMA powder.

* Some modern briar, and occasionally meerschaum, tobacco pipes sport stems made of Lucite.

* PMMA technology is utilized in roofing and waterproofing applications. By incorporating a polyester fleece sandwiched between two layers of catalyst-activated PMMA resin, a fully reinforced liquid membrane is created ''in situ''.

* PMMA is a widely used material to create deal toys and tombstone (financial industry), financial tombstones.

* PMMA is used by the Sailor Pen Company of Kure, Hiroshima, Kure, Japan in their standard models of goldnib (pen), -nib Fountain Pen, fountain pens, specifically as the cap and body material.

Biodegradation

The Futuro house was made of fibreglass-reinforced polyester plastic, polyester-polyurethane, and poly(methylmethacrylate); one of them was found to be degrading by cyanobacteria and Archaea.See also

* Cast acrylic * Organic laser * Organic photonics * PolycarbonateReferences

External links

Perspex Technical Properties

Perspex Material Safety Data Sheet (MSDS)

{{Authority control Acrylate polymers Amorphous solids Biomaterials Commodity chemicals Dental materials Dielectrics Engineering plastic German inventions Optical materials Plastics Thermoplastics Transparent materials